Reduce rework and scrap. Ensure repeatable quality. Speed up inspections & QA.

Automotive sheet metal parts must meet tight dimensional tolerances to ensure proper assembly. Even minor deviations can result in fitment issues, such as misalignments, gaps, or interference between components. Defects not detected in early production stages can disrupt the manufacturing process, delaying production schedules and increasing scrap rates.

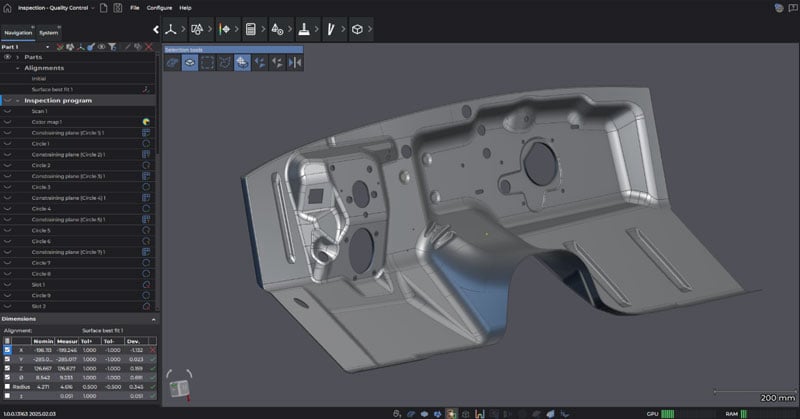

Quality control (QC) plays a critical role in detecting those deviations and ensuring parts meet stringent tolerances. However, few inspection solutions are versatile enough to accurately measure sheet metal parts regardless of environmental conditions and user expertise.